Dog hole finish board

Building the table

Printouts

Materials

- Thin strip of wood (1″ x 13″)

- 3/4″ x 24″ x 24″ piece of plywood

- 3/4″ x 3″ x 6″ piece of plywood

- 3/4″ x 4″ x 24″ piece of plywood (for jig)

- Wood glue and Epoxy

- Painter’s tape

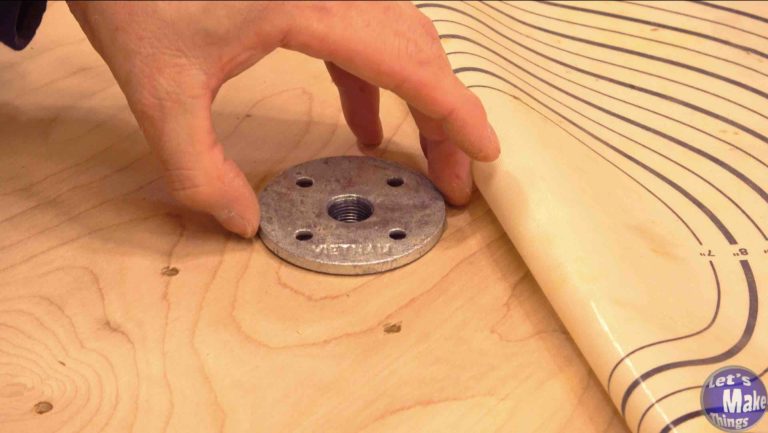

- 3/8’s Flange

- 3/8’s x 3″ Nippel

- 1/4″ thick wood strips

- (4) #6 x 1/2″ wood screws

Tools Needed/used

- Awl

- Pencil

- Permanent marker

- Hand saw

- Yard stick (or Tape measure)

- Fine ruler

- Square

- Clamps

- Glue mat

- 2″, 5/8″ Forstner bit

- 1/4″ Brad point bit

- 1″ Spade bit

- Drill press

- Bandsaw (coping saw would work)

- Hand Drill

- Sander or sanding block

The next 8 instructions come from this video

Hole placement jig

This jig is nothing more than a stick with 5 holes on it, one of which is a pivot that an awl fits in, or even a nail. All holes are drilled with an 1/8″ drill bit, which is also big enough for a pencil to fit in.

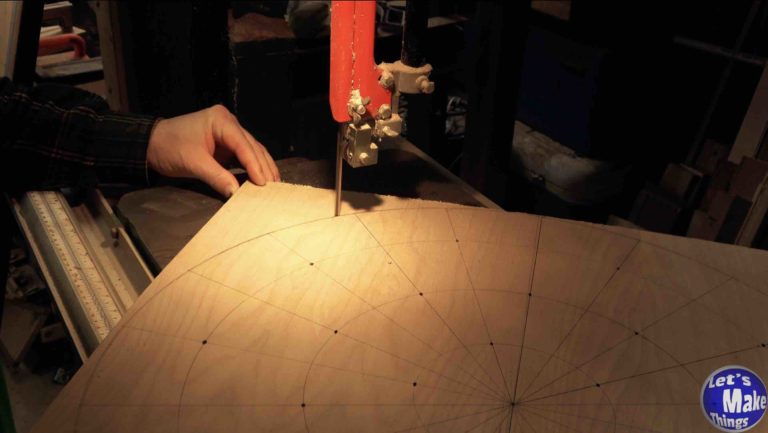

Once all holes are drilled, you’ll insert the awl into the pivot hole, a pencil in each of the other holes, and spin, completing four circles.

Plotting each circle

We’ll now want to mark where we’ll put our 2″ holes. I have a handy little sheet you can download here that will show you exactly where to plot each point. The circle is divided by the lines we drew in the past step, as well as by the circles.

Inner Circle Jig

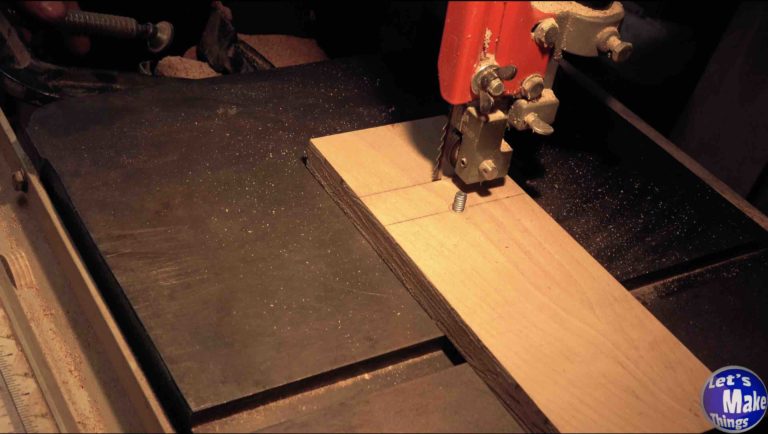

Because we want straight, half inch deep holes, this little jig will make it easy for us to get the right depth in each of the 2″ holes we make. First we’ll drill each of the 20 outer holes on the drill press, then we’ll use this jig to get the 6 inside holes that our drill press can’t reach.

Comprised of 2 pieces of scrap plywood, we’ll make it long enough that we can clamp the outside. The second plywood scrap will have a hole just big enough for our forstner bit hole. With painters tape, we can make a depth guage that will let us drill exactly a 1/2″ deep hole.

Leveling the bottom

Unfortunately, the flange will create a 1/4″ gap from the table to the bottom of your finish board, so we’ll use 1/4″ thick strips to flesh it out. I cut my strips out with a table saw, but if you don’t have a table saw, you can always pick up 1/4″ strips at your local hardware store.

Creating the pads

Tools Needed/used

- Awl

- Pencil

- Yard stick (or Tape measure)

- Fine ruler

- Square

- Utility knife (or knife of some kind)

- F-clamps and C-clamp

- Glue mat

- 5/8″ Forstner bit

- 1/16″, 1/4″ Brad point bit

- 1″ Spade bit

- Hacksaw

- Drill press

- Bandsaw

- Belt sander

- Blow torch (optional)

Materials

- 1/4″ x 1″ Carriage bolt and 1/4″ nut

- 1/4″ x 24″ threaded rod

- 3/4″ x 3 1/2″ x 10″ piece of plywood

- (26) 1/2″ x 2″ x 2″ plywood squares

- (3) 3″ x 21″ Carpet Utility runner

- Wood glue, Mod podge and Epoxy

- Painter’s tape

- (4) #6 x 1/2″ wood screws

- 1/8″ magnets (optional)

The next 6 instructions come from this video

Circle Jig

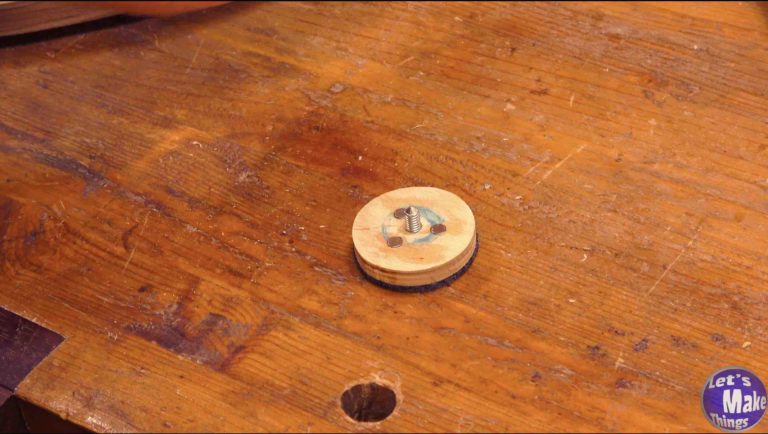

With a 3 1/2″ x 10″ piece of plywood (3/4″ thick), we’re going to make a circle cutting jig that will cut 2″ circles out of 1/2″ plywood.

We’ll draw two lines on the top and find the center of the line closest to the center of the scrap. I used a 1/16″ drill bit and drilled through, switched to a 5/8″ forstner bit and drilled in a half inch. Then finished by drilling the rest of the way through with a quarter inch drill bit. a 1/4″ x 1″ carriage bolt inserts in through the bottom.

Do you need to make this jig? No, but it makes it easier to cut the circles that will go on your finish board.

Pad Creation

Now that we’ve made our circle jig, it’s time to make the blocks that will fit on it. You’ll need to cut out (26) 1/2″ x 2″ x 2″ squares. On each square, you’ll need to find the center. By connecting the diagonals, you’ll achieve this.

Once you’ve found the centers, use a 1/4″ brad point bit to drill them out.

Adding Carpet Utility Runner

We’ll cut out (3) 3″ x 21″ pieces of carpet utility runner. If you haven’t heard of this, check out my webpage explaining this magical material. With mod podge, we’ll glue the tracker runner to the 26 blocks we cut and shaped in the last step, finishing by clamping it together.

Using the circle Jig

At this point, using the jig is simple. We’ll cut half way on the line we drew that’s closest to the edge and turn off the drill press. The jig will need to be clamped down and I found a c-clamp did a great job.

With the jig in place, the rest is a snap: insert the 1/4″ carriage bolt into each square and spin.

Adding small magnets (Optional)

I added magnets to the center pad so that when I store the finishing plate on its side, it won’t fall out. The others use the 1/4″ hole we drilled, but, due to the flange, that hole is bigger. This is a work around.

Not necessary, but an option.

Making finish blades (optional)

Tools Needed/used

- Awl

- Pencil

- Tape measure

- Utility knife (or knife of some kind)

- 1/16″, 1/4″ Brad point bit

- Hand drill (optional)

- Table saw (optional)

Materials

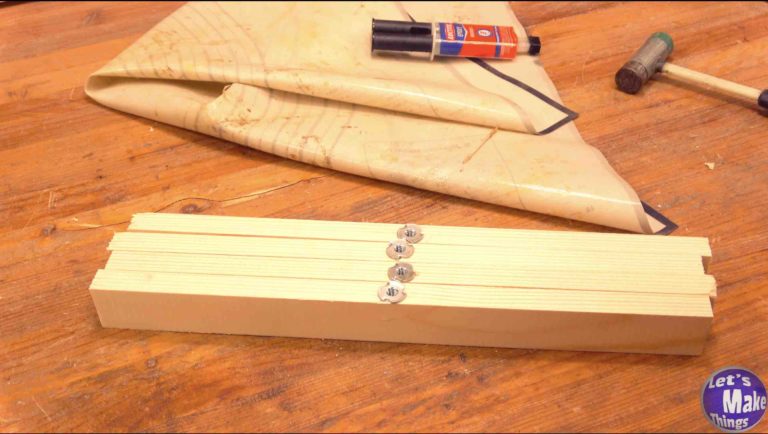

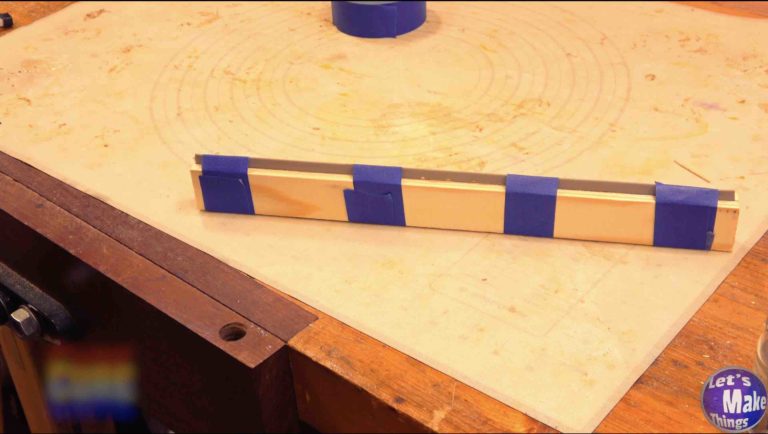

- (2) 1″ x 2″ x 16″ Pine lumber

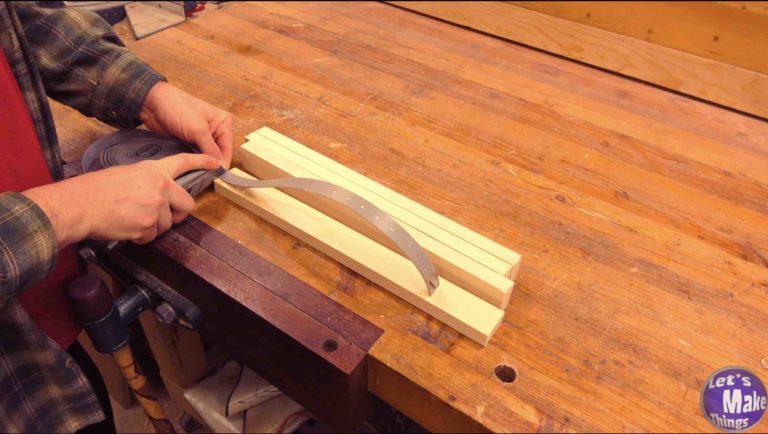

- (2) 16″ Plumbing straps

- (2) 1/4″ T-nuts

- Epoxy

- Painter’s tape

- (4) #6 x 1/2″ wood screws (optional)

The next 6 instructions come from this video

Tip Jar

If you found any errors on the page, please contact me and let me know!