Make a floating belt sander fence

Belt sanders are powerful tools for quickly removing material and smoothing surfaces, but they often lack precision, making them challenging to use for fine woodworking tasks. The biggest problem that comes with this is that there isn’t a reference point we can judge our stock. To get around that problem, we’ll use a table saw fixture that will give us a means to judge how vertical our stock is in our hands as we use it.

watch all steps in this video before starting

Please use the material and tool list below as a guide to finding the products locally.

Downloadable file

Materials

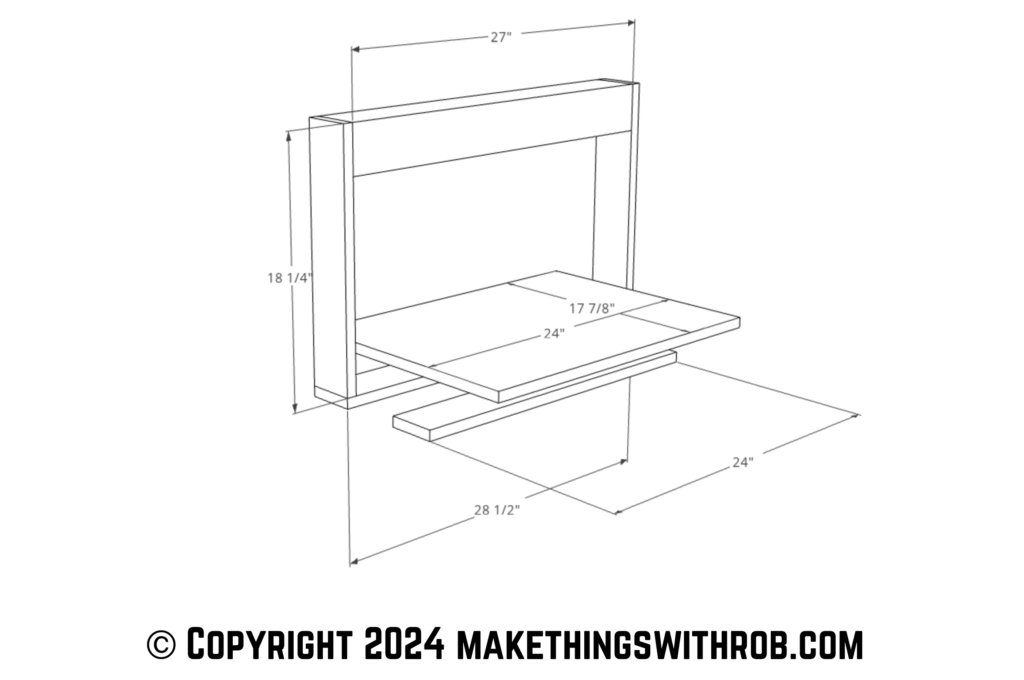

- (2) 3/4″ x 3 1/2″ x 18 1/4″ Soft or Hardwood

- 3/4″ x 3 1/2″ x 28 1/2″ Soft or Hardwood

- 3/4″ x 3 1/2″ x 24″ Soft or Hardwood

- 3 1/2″ x 3 1/2″ x 27″ Soft or Hardwood (Must be square)

- 3/4″ x 24″ x 17 7/8″ Plywood

- 7/8″ x 16″ Dowel

- (4) 5/16″ x 2″ Carriage bolts

- (4) 5/16″ washers

- (4) 5/16″ lock nuts

- (10) 2 1/2″ Screws

- Glue (Wood)

- Paste wax (Optional)

Tools Needed/used

- Table saw or circular saw (to cut plywood to size)

- Drill press & drill

- 7/8’s Forstner bit (Optional)

- Quad Vise (Optional, but oh so nice)

- Marking gauge (Optional, but oh so nice)

- Ruler

As an amazon associate I earn from qualifying purchases.

Step by step instructions

1. Materials

You won’t need a lot to make this. I made mine with 6 pieces of lumber…it’s a simple build with scalable options for your sander. I can’t imagine that this wouldn’t fit any bench top belt sander, but please, if you find that yours won’t, use the email below to let me know. I’ve included a PDF that shows how I made mine…and a sketchup file so that you can scale yours.

2. Attaching the base plate (PT1)

In this step I used my sander as a template to mark and then drill holes out so that it could be attached to my belt sander. Because I’m using carriage bolts, I used a forstner bit to drill holes that would allow my bots to be below the surface.

3. Attaching walls to the base board

Attaching the walls are like build 2×4 framed walls, except we won’t enclose the top just yet. Because screwing into end grain isn’t good, I used a tip from bitesize 162 (shorts video here) and added 7/8’s dowels before using screws to screw them together.

5. Attaching the fence

The fence will now attach to both sides of the walls we attached back in step 3. You’ll want to make sure that they are at a 90˚ with the bed of the belt sander. I again drilled holes and used dowels and then drilled into those dowels, again like step 3. I also used a third screw on each side drilled directly into the end grain for stability.

6. Floating? And operation

The idea to ‘float’ the fixture is based on the idea that you don’t want to use one part of the belt sander all the time. Instead, we’ll be able to move the fence when we want to use other parts of the sandpaper, thus preserving more of it in the future. I also wanted to be able to take the fixture off very easily. There are times where I have very large surfaces I want to sand off but don’t want to be hindered by a permanent structure. This easily allows me to remove the fixture at any time and put it back in just a couple steps.

The operation is very simple: We don’t press against the fence, we simply use it as an index, allowing us the ability to hold it upright and know when we are at a 90. If you plan on really pushing into the fence, you’ll want to make the walls a lot wider on the edges to support the added stress.

Tip Jar

If you found any errors on the page, please use my email below and contact me!