Build a steel vise bench appliance

Woodworking bench vises are traditionally built into the bench: Great for woodworking projects, terrible for cutting or working on metal. But mounting a steel vise to the surface can get in the way of larger projects. We can get around that by making a vise on a jig that’s easily able to be removed when not needed. I’ve got two different jigs I’ve come up with that will work: One with a woodworking vise, the other if you don’t have a vise but don’t want to mount your steel vise to the table.

watch all steps in this video before starting

Please use the material and tool list below as a guide to finding the products locally.

Materials

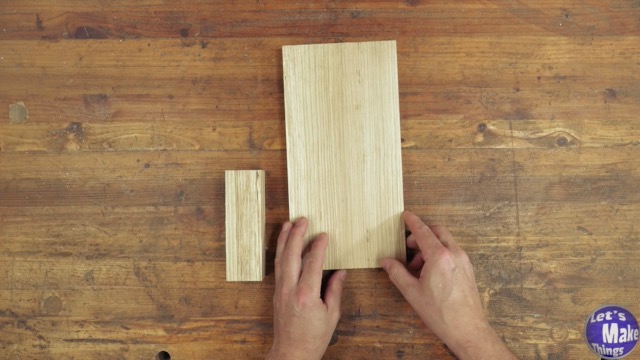

- 3/4″ x 6″ x 12″ Hardwood (rift or quartersawn are better choices)

- (2) 3/4″ x 1 3/4″ x 5 3/4″ Hardwood (Glued together)

- (4) 3/8″ x 1 1/2″ Stove bolt (flat head)

- (4) 3/8″ Lock nuts

- (4) #14 x 1 1/2″ Flat head screws

- Double sided tape

- 5/8’s bolt (with 4 inches of non threading) (V.2 Only)

- Goehner’s bench vise (Highly recommend this)

Tools Needed/used

- Drill press / Hand drill

- 3/16″, 3/8″ Bradpoint bit

- 5/8″ Spade bit

- Countersink bit

- Ruler

- Marking gauge (Optional, but oh so nice)

As an amazon associate I earn from qualifying purchases.

Step by step instructions

Tip Jar

If you found any errors on the page, please use my email below and contact me!