Fence creeper jig

August 12th, 2024

One excellent function of a table saw is making precise cuts parallel to the fence, whether they’re long or short. But what if you need to make a thicker cut? While a stacked dado blade is an option, removing and reinstalling it can be cumbersome, and dado blades can be costly and require sharpening or replacement with frequent use.

An easier solution is to make a series of cuts, adjusting the fence after each pass to achieve the desired thickness. This method, though, often involves a tedious game of ‘bump the fence’ to get the exact width you need, which isn’t very efficient. Achieving fine adjustments can be especially challenging.

These are all great reasons to build a Creeper Fence Jig. So, let’s get started!

ATTENTION: These plans are yours to use…they are offered as a gift from me to you. You have every right to use them to make this project for yourself, but please, do not sell or give these plans away as your own. I make absolutely no money off of these so I would appreciate those who view these plans to abide by basic copyright laws.

watch all steps in this video before starting

Please use the material and tool list below as a guide to finding the products locally.

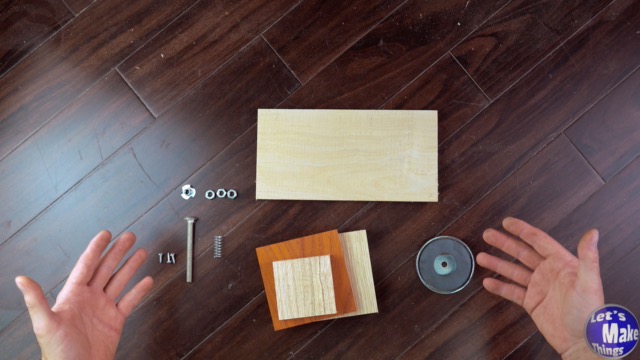

Materials

- 3/4″ x 4 1/2″ x 4 1/2″ Hard or softwood (base)

- 3/8″ x 4 1/2″ x 4 1/2″ Hard or softwood (base lid)

- 1/2″ x 3″ x 3″ Hardwood (wheel knob)

- 1/2″ x 5 1/2″ 8 1/2″ Hard or soft wood (creeper)

- 5/16-18 T-nut

- 5/16-18 x 3 1/2″ Carriage bolt

- Spring that will fit on a 5/16″ bolt

- (2) 5/16-18 Hex nuts

- (3) 5/16-18 Washers

- Cabinet knob (optional)

- 3″ magnet

- Thread lock (permanent)

- Double sided tape

- Wood glue

- Epoxy

Tools Needed/used

- Table saw

- Bandsaw

- Drill press

- Belt and disk sander (optional)

- Router (optional)

- Clamps

- 5/16″, 3/8″ Brad point bit

- 3/8″ Twist bit

- 3/4″ Forstner bit

- Compass

- Marking gauge (optional, but oh so nice)

As an amazon associate I earn from qualifying purchases.

Step by step instructions

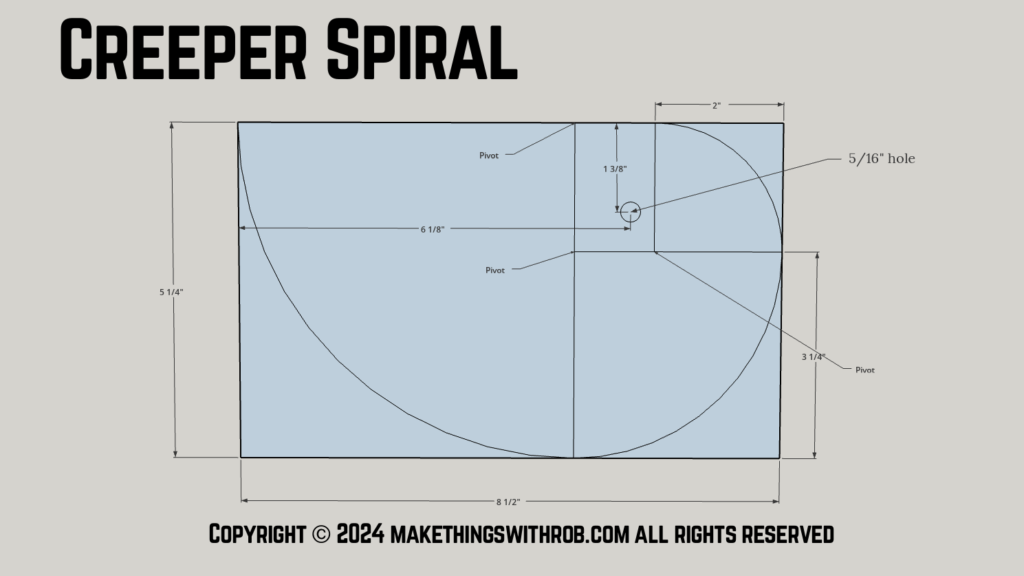

2. Making the creeper spiral

In this step we’ll make a less detailed version of the fibonacci spiral–we’re only going to use 3 squares altogether. I have a premeasured mark for the center so that it rotates on the arcs just right (check the instructions or click the image with this step).

3. Magnetic base and lid

Those 3 inch magnets are a pain to remove from the table top, so we’ll use a bolt to pull it up and to set it back down. This involves creating a base with a upper and lower compartment. I made it circular and just slightly larger than the magnet due to it needing to be close to the fence.

4. Simple studded knob

We’ll make a very simple studded knob. I showed how to make a simple version, but from here on out you’ll see a three sided knob that I switched it with to match the look I was going for. I encourage everyone to make knobs look beautiful, you’ll love to use them!

5. Magnetic plunge assembly

The magnetic plunge assembly needs to be assembled just right for it to work. I used a bolt that fit the length of my spring, but you may have to alter a spring. Speaking of spring, it is slightly necessary. As the table saw runs, it might try to cause it to spin away from the fence, so you’ll constantly be putting it back to use it. A spring keeps it tight in place.

6.Operation

Operation is simple: it rolls on the opposite side of the fence from the blade and spins towards the back of the saw. When one cut is made, the fence is unlocked, the spiral is turned by looking at the tape on the saw and adjusting by a few micro measurements. The fence must be locked again (this does NOT hold the fence in place) before use, and the stock is passed through the blade again. Repeat until the desired width has been created.

Tip Jar

If you found any errors on the page, please use my email below and contact me!