Router Dado Track

September 26th, 2024

Straight dados are crucial for strong, accurate joints in woodworking projects. However, achieving that level of precision can be challenging when relying solely on a straight edge, as even the slightest misalignment can throw off the cut. This step-by-step guide will show you how to create a reliable, free-to-make jig using uni-strut, bearings, and hardboard.

This jig allows you to easily set up and cut perfectly straight dados every time, without needing to use a double straight edge set up. This simple, DIY jig will save you time and frustration, giving you clean, precise results with ease.

ATTENTION: These plans are yours to use…they are offered as a gift from me to you. You have every right to use them to make this project for yourself, but please, do not sell or give these plans away as your own. I make absolutely no money off of these so I would appreciate those who view these plans to abide by basic copyright laws.

watch all steps in this video before starting

Please use the material and tool list below as a guide to finding the products locally.

Materials

- 1-5/8″ X 13/16″ X 5′ Unistrut

- 3/4″ x 7″ x 10 1/2″ Plywood (base)

- 3/4″ x 3 5/8″ x 10 1/2″ Plywood (arm)

- (2) 1/2″ x 2″ Oak dowel

- 3/16″ x 4″ x 48″ Hardboard

- (2) 3/16″ x 5″ x 12″ Hardboard (Optional used as a jig)

- 1/4″ x 7″ x 10 1/2″ Plexiglass

- (2) Bearings (1/2″ ID-1 1/8 OD)

- (2) 1/4″ x 1 5/8″ Carriage bolts

- (2) 1/4″ Wing nuts

- (2) 1/4″ Fender washers

- (8) #8-3/4″ Flat head screws

- (10) #6-1/2″ Flat head screws

- (2) 1/4″ Threaded wood inserts

- Threadlock (permanent)

- Double sided tape

- Epoxy

Tools Needed/used

- Router

- Bandsaw

- Table saw

- V-groove router bit

- Flush cut bit

- 3/8, 1/4, 3/16, 1/16 Brad point bits

- Countersink bit

- 2″ Carbide forstner bit

- Single flute countersink bit

- Allen bit set (optional)

- Screwdriver

- Marking gauge (optional, but oh so nice)

- Chalk Pencil (optional)

As an amazon associate I earn from qualifying purchases.

Step by step instructions

1. Materials

You will need unistrut for this project. I’ve heard some people say that unistrut isn’t necessarily straight, and that is true, it’s not always true. Be sure you lay it on the floor of the store and make sure it’s flat against it. I’ve seen bent ones, and this makes the problem go away.

Plexiglass should be the thickness of your router plate. Bearings could be 3/8’s ID, but I’d definitely go with 1/2 inch. Everything else should be above in the material’s list.

2. Carriage base

The carriage base should be 2 inches wider on either side of your router base, and about an inch wider at the top (see image). We’ll mark around our router base and use the bandsaw to cut out the center. When done, the router should fit inside of the cut made.

Be sure to use 3/4″ plywood here.

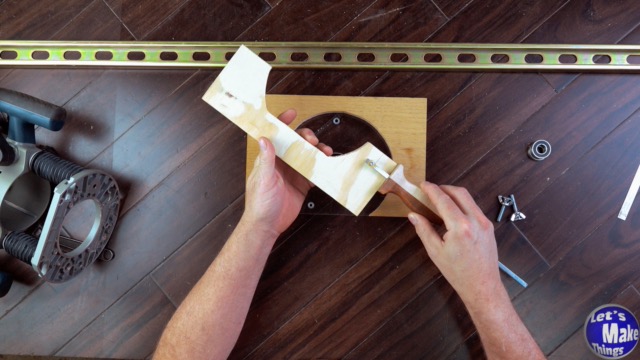

3. Upper carriage arm (shape)

We’ll take the carriage base we cut and use it as a template for the upper arm, which should drape over the unistrut to the back edge. A line also needs to be made between the partial sphere.

A little double sided tape will make getting the template to work better for you.

This will need to be cut on the bandsaw as well.

6.Finalizing the carriage base

Finalizing the carriage base involves drilling and adding threaded inserts. With 1/4″ inserts, you’ll want to use a 3/8’s drill bit, but only as long as it’s tight enough it won’t slip. I used epoxy on the threading…which I highly recommend.

9. Demonstration

Click the image for a really quick demonstration. ALWAYS be sure you use step routing and don’t try to force the final depth you want as it can destroy your router and with enough force, it will not be good for your dado track.

→ Click here to see a bitesize showing how to set up a plunge router. ←

Tip Jar

If you found any errors on the page, please use my email below and contact me!